Hiii,I am Sk.riyaz basha. I have Completed my sevel engineering.but I am interested in electronis because i love technology,and solar energy and nano technology.Reading books,writing poems,talking with different people ,traking are my hobies.After complecte sevel engineering I have started learning with Vigyan Ashram as a D B R T [Diplama in basic rular technolagy].

This

is my self .now startet my project information .

What

is Polyhouse ?

A

polytunnel (also known as a polyhouse, hoop greenhouse or

hoophouse, or high tunnel) is a tunnel made of polyethylene,

usually semi-circular, square or elongated in shape.

What

is automation poly house ?

The

main goal is to

build

a miniature polyhouse which is equipped with

an

automatic monitoring system. This monitoring

system

will constantly monitor the conditions in the

polyhouse

to ensure that it remains a

t

preset

temperature

,

light

humidity

conditions.

If

these conditions differ from the preset levels, the

monitoring

system will automatically turn on certain

devices

to return the polyhouse to the required

conditions.

Automatically

control the crop

growing

environment

within

the walls so that

any

type of plants can be

grown

all year round. Eliminates the risk of the

polyhouse

not being kept at crop specified conditions

due

to human error. Minimizes the labor costs crop

involved

in maintaining a playh

ouse.

Customer will

be

able to define their crop preferred polyhouse conditions and have the

system function as specified.

This

will be a “plug and play” product.

What

is the main difference normal polyhouse and automation polyhouse

Normal

polyhouse :Polyhose is normal iroan structure and coverd some

polythin covers and

saporting some

galavanized pipes .

A

polytunnel (also known as a polyhouse, hoop greenhouse or

hoophouse, or high tunnel) is a tunnel made of polyethylene, usually

semi-circular, square or elongated in shape .

automation

polyhouse : If the temperature exceeds the maximum

value,

the plc will then turn on the fan. If the

temperature

drops below the minimum value, the

bulb

will turn on. As for the photodiode, if the

polyhouse

is exposed to insufficient light,

it

will send

a

signal to the plc. The plc will then process the

signal

and turn on the artificial light in the polyhouse.

As

for the humidity sensor, it will detect a change in

humidity

levels of soil and send a signal to the plc. If

the

humidity level is

not

within the required range,

the

water supply will be turned on or off. The plc will

be

the central processing unit which will translate the

input

signals from the sensors and turn on or off the

necessary

devices to maintain the polyhouse at the

preset

levels.

“To

maintain environmental conditions inside the

house

for better production of crop with the help of

PLC

which make it suitable for productive uses and

help

improve crop quality and quantity.”

SYSTEM

IMPLEMENTATION:

Programmable

Logic Controller

We

will use Arduino uses 12V dc power supply.

Actual

programming is stored in the Arduino microcontroller.

Matireal

requerd :

We

will use humidity sensor for sensing the

humidity

of soil. After that this

signal

is

send

to plc. In that plc a particular set point

is

given and if it is below or above it take

action

likewise .

Temperature:

We

will use thermocouple as temperature

sensor.

Temperature is sense an after that

this

signal is send to Arduino. In that plc

a

particular

set point is given and if it is below

or

above it take action likewise.

Exhaust

Fan:

The

fans should deliver the required air

at

15mm static pressure. The maximum

center

to center spa

cing

between the two

fans

should be of 7.5m. The height of the

fans

is to be determined based on the plant

height

which is proposed to be grown in the

greenhouse.

The fan blades and frame are to

be

made of non

-

corrosive

materials like

aluminum/stainless

steel .

humidity control :

humidity control :

:

The

humidistat coupled to water

circulating

pump to control the relative

humidity

of soil. Here we maintain the

relative

humidity of soil. This is one type of

watering

system in this soil sensor is use to

find

out humidity

in

soil and if it is less then

motor

pump start and water is giving to the soil .

230

volt motor :

The

motor on will be moistuer <700 and motor offautomatically

>300

soil moistuer .

will

be switch in normally close to normally open .

Main

heart was this project arduino because arduino will be send a

signel

relay and some kind of sensors Exm : tempreatuer & moistuer

LCD :(liquid crystal display)

LCD (liquid crystal display) is the technology used for displays in notebook and other smaller computers. Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

2Channel relay module

The Arduino Relay module allows a wide range of microcontroller such as Arduino, AVR ,PIC, ARM with digital outputs to control larger loads and devices like AC or DC Motors, electromagnets, solenoids, and incandescent light bulbs. This module is designed to be integrated with 2 relays that it is capable of control 2 relays.The relay shield use one QIANJI JQC-3F high-quality relay with rated load 7A/240VAC,10A/125VAC,10A/28VDC.The relay output state is individually indicated by a light-emitting diode.

- COM- Common pin

- NC- Normally Closed, in which case NC is connected with COM when INT1 is set low and disconnected when INT1 is high;

- NO- Normally Open, in which case NO is disconnected with COM1 when INT1 is set low and connected when INT1 is high.

- INT 1- Relay 1 control port

- INT 2- Relay 2 control port

Arduino is an open-source electronics platform based on easy-to-use hardware and software. Arduino boards are able to read inputs - light on a sensor, a finger on a button, or a Twitter message - and turn it into an output - activating a motor, turning on an LED, publishing something online.

iam using this arduino uno because this is able to read inputs -light on a sensor.

Proses in this project :

First i am connect a LCD connections because LCD was a main part of this project.

Easy to identify which load is on or off at this time .

which sensor will be work or not i am easy to identify help with LCD only . so first

i will sagest to connect a LCD connections .

Now i can tell you LCD connection with circuit diagram :

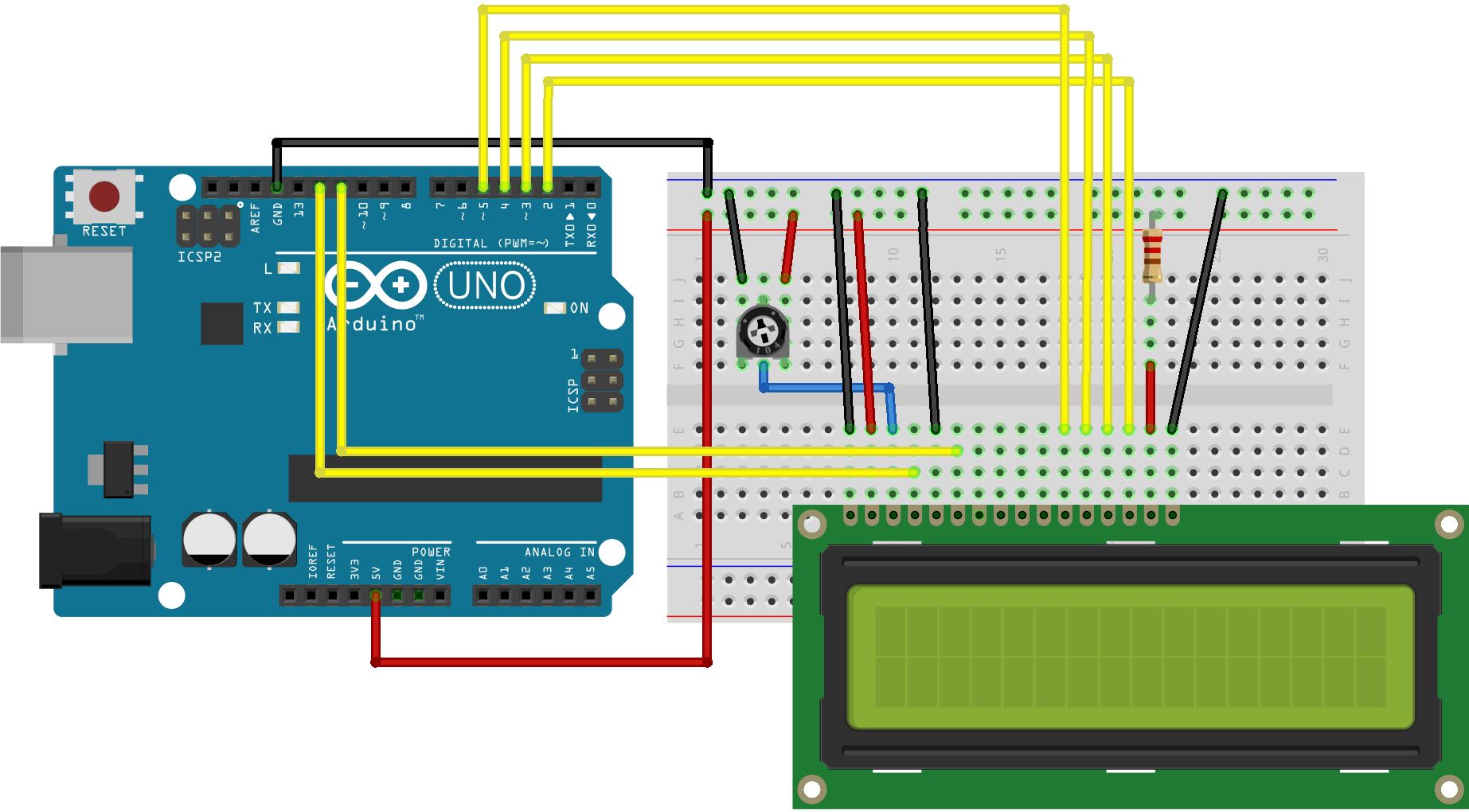

LCD Connections with Arduino uno

Before wiring the LCD screen to your Arduino or Genuino board we suggest to solder a pin header strip to the 14 (or 16) pin count connector of the LCD screen, as you can see in the image above.

To wire your LCD screen to your board, connect the following pins:

- LCD RS pin to digital pin 12

- LCD Enable pin to digital pin 11

- LCD D4 pin to digital pin 5

- LCD D5 pin to digital pin 4

- LCD D6 pin to digital pin 3

- LCD D7 pin to digital pin 2

More information for LCD connections with arduino

https://www.arduino.cc/en/Tutorial/HelloWorld

Now connect a LCD with aruino look like this .

DHt-11 sensor connections with arduino uno :

It's time to connect a temperature & humidity sensor with ardino

First i can show a circuit diagram

Temperature connection is a too easy with arduino

DHT-11 sensor had a three terminals

1. vcc

2.ground

3.data

*Now connect a sensor vcc & ground pins with arduino.

* i am define a data pin a arduino 6 no pin .

So this is a arduino connections .

you want a more information open this link

http://www.getmicros.net/arduino-dht11-sensor-example.php.

you can complete a connections look like this

After complete look like thise

Moisture sensor connections with arduino uno :

Now connect a Moisture sensor with ardunio

Ok first i can show circuit diagrem with arduino

the moisture sensor connections its too easy because this sensor have a

only four terminals but i can use a three terminals .

Pin Assignment

There

are 4 pins used to interface Moisture Sensor board to arduino.

User may used either Digital Output (DO) or Analog Output (AO) or both

pin as output pin.

- VCC

- GND

- Digital Output (DO)

- Analog Output (AO)

i am define data arduino pin 9 .

After connect look like this

Example Code

// Soil Moisture Sensor Hygrometer example code

// Code author: http://electron-space.blogspot.com

// Interface Description (4-wire)

// VCC: 3.3v-5v

// GND: GND

// DO: Digital output interface (0 and 1) threshold taken from potentiometer

// AO: Analog output interface

const int moistureAO = 1;

const int moistureDO = 13;

int AO = 0;

int DO = 0;

int tmp = 0;

void setup (){

Serial.begin(9600);

Serial.println("Soil moisture sensor");

pinMode(moistureAO, INPUT);

pinMode(moistureDO, INPUT);

}

void loop ()

{

tmp=analogRead( moistureAO );

if ( tmp != AO )

{

AO=tmp;

Serial.print("A=");

Serial.println(AO);

}

tmp=digitalRead( moistureDO );

if ( tmp != DO )

{

DO=tmp;

Serial.print("D=");

Serial.println(DO);

}

delay (1000);

}

you wan a more information see this link

https://docs.google.com/document/d/1Z5C1MgRsdo8y6ipWAQN2y7p9sYSn-G3oF8FhCulNeAk/mobilebasic

Which loads connect with sensors

1.temperate sensor connect Exhaust Fan .

2.Moisture sensor connect a drip irrigation system .

3.LCD connect connect a each too sensors .

Testing of process wiring and troubleshooting

The crux of all troubleshooting was testing

of through process wiring. The entire system had to

be connected to the arduino. In numerable problems

were encountered in this process specially like. Wire

not been connected to the proper port. Wiresall connected at wrong points either on the junction boxand terminal strips. Few instruments were notconneted to the arduino.

Testing of pump and automatic

-

The pump had to be tested for its working

and efficiency. We also needed to automate the

pump. The pump is automated by connecting a relay

of 5V to 230V so that once you connect the pump

wiring to the relay, the pump starts as soon as a 5v

signal is given to it by the PLC.

result

In this way we maintain the environment of

polyhouse using arduino and sensors.

In this way after taking lots of efforts

we are

successful to make automated Polyhouse. arduino

have some Digital as well as some Analog input

after sensing them it will take the decision as per

ladder logic and handle number of digital outputs

for polyhouse.

Due to automation there is no necessity of

number of worker to handle farm. Only one trend

person will easily handle the polyhouse.

In this project i can say this polyhouse is nota easy as it seems . It has great importance as a form as well as i society During this project we realize that environment control processes are very precise well controled .using arduino techniques we can automate the whole polyhouse.

As we see crop is one of the one of the importance

and to increase the crop polyhouse is best option .in this way we will make automated polyouse using arduino .An we provide farmers a new wold of technology ,because of this project farmer will become rich and everyone who think that forming is

form villag people ot illiterate people they will also do farming ad improving this system .

Block diagrams

0 टिप्पणी(ण्या):

टिप्पणी पोस्ट करा